|

|||||||||||||||

|

|

|||||||||||||||

|

|||||||||||||||

|

The

Kosmos whaling fleet 1948/49 season

|

|

|||||||||||||||

|

|

|||||||||||||||

|

|||||||||||||||

|

The

Kosmos whaling fleet 1948/49 season

|

|

Introduction The Kosmos whaling company was based in Sandefjord, Norway, and owned and managed by the Sandefjord ship owner Anders Jahre. This fleet was typical of all the Norwegian and British pelagic whaling fleets which voyaged the Antarctic waters in the years immediately preceding and following the Second World War. |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The factory ship - Kosmos III The command centre of the fleet was the factory ship - in the case of the 1948/49 season this was Kosmos III (Though Kosmos IV joined the fleet later on).  The

factory ship was a large vessel, several hundred feet in length, with a

forward superstructure housing the bridge, communications centre and officers

accommodation, and amidships and aft superstructures housing deck crew

accommodation and deck plant rooms. Kosmos III made her first maiden voyage

in 1947, and was the most modern and best equipped whaling factory ship

of the era. The vessel was equipped with a slipway aft, which cut through

the below decks and the aft superstructure at an angle, from just below

the waterline, to the level of the main deck. With the aid of winches aft

of the forward superstructure and amidships, an entire whale could be hauled

up onto the deck for butchering. The main deck was large enough to accommodate

several whales at a time. During the 1948/49 season, it was not uncommon

for the butchering crew to butcher up to five whales a day. The

factory ship was a large vessel, several hundred feet in length, with a

forward superstructure housing the bridge, communications centre and officers

accommodation, and amidships and aft superstructures housing deck crew

accommodation and deck plant rooms. Kosmos III made her first maiden voyage

in 1947, and was the most modern and best equipped whaling factory ship

of the era. The vessel was equipped with a slipway aft, which cut through

the below decks and the aft superstructure at an angle, from just below

the waterline, to the level of the main deck. With the aid of winches aft

of the forward superstructure and amidships, an entire whale could be hauled

up onto the deck for butchering. The main deck was large enough to accommodate

several whales at a time. During the 1948/49 season, it was not uncommon

for the butchering crew to butcher up to five whales a day. |

||||||||||||||||||||||||||||||||||||||||||||||||||||

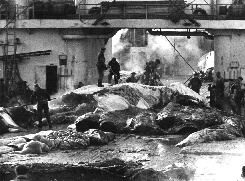

The

butchering process involved removing the blubber from the whale, and cutting

it into manageable sizes which could be dropped through a hatch in the

deck, into the rendering area below. Here the blubber went into large tryworks

- which on Kosmos III were fuelled by diesel. The blubber would be melted

and rendered to oil, which would be stored in large holding tanks. Some

of the meat was also processed as meat-extract for animal feed or agricultural

fertiliser. But whale meat was a by-product on such voyages, one which

was often simply thrown overboard. The

butchering process involved removing the blubber from the whale, and cutting

it into manageable sizes which could be dropped through a hatch in the

deck, into the rendering area below. Here the blubber went into large tryworks

- which on Kosmos III were fuelled by diesel. The blubber would be melted

and rendered to oil, which would be stored in large holding tanks. Some

of the meat was also processed as meat-extract for animal feed or agricultural

fertiliser. But whale meat was a by-product on such voyages, one which

was often simply thrown overboard. |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Certain internal organs such as the liver were rich in oils which were rendered separately. The sperm whale was a prized catch, supplying valuable spermaceti - a waxy oil in the head of the whale which was rendered separately and used for candle production and various industrial processes. |

||||||||||||||||||||||||||||||||||||||||||||||||||||

Some

organs - such as the intestines would be processed as animal fodder, though

usually these were discarded. The butchering process was essentially manual,

the crew of 400 working two 12 hour shifts. It was hard work, using flensing

tools and long knives the meat and blubber would be separated from the

carcass. Winches would be used to pull large strips of blubber or meat

away from the carcass, whilst the crew worked with their flensing tools.

The deck was also equipped with large mechanical grabs which allowed parts

of the carcass to be ripped apart and manoeuvred about the deck area. The

entire deck area was covered in timber - a new deck laid for each voyage

- to protect the flensing tools - and the steel deck underneath from damage

during the butchering process. Each season, during the voyage home to Norway,

the crew would rip up the deck and throw the old planks overboard, and

replace the decking with new timbers before the next season. Some

organs - such as the intestines would be processed as animal fodder, though

usually these were discarded. The butchering process was essentially manual,

the crew of 400 working two 12 hour shifts. It was hard work, using flensing

tools and long knives the meat and blubber would be separated from the

carcass. Winches would be used to pull large strips of blubber or meat

away from the carcass, whilst the crew worked with their flensing tools.

The deck was also equipped with large mechanical grabs which allowed parts

of the carcass to be ripped apart and manoeuvred about the deck area. The

entire deck area was covered in timber - a new deck laid for each voyage

- to protect the flensing tools - and the steel deck underneath from damage

during the butchering process. Each season, during the voyage home to Norway,

the crew would rip up the deck and throw the old planks overboard, and

replace the decking with new timbers before the next season. |

||||||||||||||||||||||||||||||||||||||||||||||||||||

Kosmos

III was a modern whaling vessel in 1948, having completed her maiden voyage

the previous year. It was a floating community, home for some 400 men,

with all the necessary facilities for eight months at sea. Below decks,

there was a pig sty with space for 100 pigs, which would be fattened and

slaughtered at sea to provide food for the crew. There was a complete metalwork

shop where deck tools were made and repaired, as well as a fully equipped

hospital and operating theatre - a grim necessity in case of injuries from

the work on deck. In the days before communications satellites , the fleet

relied on short-wave radiotelegraphy - mainly morse code, to keep in touch

with home and return their weekly harvest reports. The Norwegian radio

broadcast a daily news summary in Norwegian, which was typed up and circulated

amongst the crew. Kosmos

III was a modern whaling vessel in 1948, having completed her maiden voyage

the previous year. It was a floating community, home for some 400 men,

with all the necessary facilities for eight months at sea. Below decks,

there was a pig sty with space for 100 pigs, which would be fattened and

slaughtered at sea to provide food for the crew. There was a complete metalwork

shop where deck tools were made and repaired, as well as a fully equipped

hospital and operating theatre - a grim necessity in case of injuries from

the work on deck. In the days before communications satellites , the fleet

relied on short-wave radiotelegraphy - mainly morse code, to keep in touch

with home and return their weekly harvest reports. The Norwegian radio

broadcast a daily news summary in Norwegian, which was typed up and circulated

amongst the crew. |

||||||||||||||||||||||||||||||||||||||||||||||||||||

The

harpoon vessels The

harpoon vessels

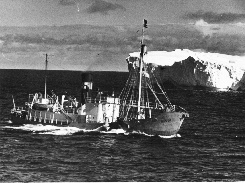

Kosmos III was kept busy by a fleet of 10 harpoon vessels - smaller craft which were equipped with a harpoon cannon on the bow. These small vessels, each with a crew of about 20 men, plied the whaling grounds in search of whales. Whilst most vessels hunted, some would be on standby - to undertake repairs, or to act as buoy-vessels which would look after the whales which the other ships had killed, until these were towed to the factory ship. |

||||||||||||||||||||||||||||||||||||||||||||||||||||

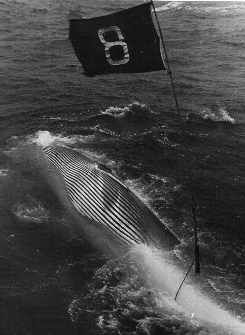

When

a whale was killed, the crew would move alongside the whale and set a float

onto the whale to mark its position. Some whales float naturally when they

are killed, whilst others take in water and sink. The harpoon vessels were

equipped with compressors, which could be used to pump air into the whale's

abdominal cavity thus inflating the whale to keep it afloat. The venting

of this air could be an unpleasant process for the butchering crew. A heavy

rope would also be attached to the fluke of the whale, so that it could

be tied off to the ship. When one of the harpoon vessels had enough whales

- supplemented by the catch from other vessels in the fleet, it would sail

to the factory ship, often with 3 or 4 whales tied along each side of the

vessel. When

a whale was killed, the crew would move alongside the whale and set a float

onto the whale to mark its position. Some whales float naturally when they

are killed, whilst others take in water and sink. The harpoon vessels were

equipped with compressors, which could be used to pump air into the whale's

abdominal cavity thus inflating the whale to keep it afloat. The venting

of this air could be an unpleasant process for the butchering crew. A heavy

rope would also be attached to the fluke of the whale, so that it could

be tied off to the ship. When one of the harpoon vessels had enough whales

- supplemented by the catch from other vessels in the fleet, it would sail

to the factory ship, often with 3 or 4 whales tied along each side of the

vessel. |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Most of the harpoon vessel crew were hired for that particular vessel, though often they were moved from vessel to vessel to keep the fleet manned as best as possible. Thousands of miles away from home, replacement crew members to cover sickness or injuries were impossible to come by.  This was particularly the case for the harpooners - who were the very elite

of the fleet. For the crew of the harpoon ships, a good harpooner was worth

his weight in gold, as the entire crew was paid according to a complicated

system whereby each man received a share in the value of the harvest. Sometimes

a harpooner would be injured or fall sick, in which case another crewman

would be appointed to fill in for him - usually after a long discussion

amongst the crew, whose earnings were dependent on the skill of the harpooner.

During the 1948/49 season, several harpooners were transferred from one

harpoon vessel to another.

This was particularly the case for the harpooners - who were the very elite

of the fleet. For the crew of the harpoon ships, a good harpooner was worth

his weight in gold, as the entire crew was paid according to a complicated

system whereby each man received a share in the value of the harvest. Sometimes

a harpooner would be injured or fall sick, in which case another crewman

would be appointed to fill in for him - usually after a long discussion

amongst the crew, whose earnings were dependent on the skill of the harpooner.

During the 1948/49 season, several harpooners were transferred from one

harpoon vessel to another. |

||||||||||||||||||||||||||||||||||||||||||||||||||||

Life

at sea in the whaling fleet was extremely hard. The Antarctic weather was

extremely cold, especially at the start and end of the season. Storms were

frequently encountered, bringing their own special dangers - particularly

over-icing - whereby the deck and superstructure would be quickly covered

with near frozen sea water, which would turn to ice upon hitting the cold

steel. Such a vessel could quickly become unstable, unless the all hands

went on deck and broke of the ice with wooden mallets and shovels. The

risk of capsizing in the frozen Antarctic waters, possibly hundreds of

miles from the nearest help was to be avoided at all cost. Maritime clothing

was not what it is today, everything became waterlogged quickly, and even

fur and sealskin clothing was heavy to wear and prone to becoming waterlogged

and frozen stiff. Life

at sea in the whaling fleet was extremely hard. The Antarctic weather was

extremely cold, especially at the start and end of the season. Storms were

frequently encountered, bringing their own special dangers - particularly

over-icing - whereby the deck and superstructure would be quickly covered

with near frozen sea water, which would turn to ice upon hitting the cold

steel. Such a vessel could quickly become unstable, unless the all hands

went on deck and broke of the ice with wooden mallets and shovels. The

risk of capsizing in the frozen Antarctic waters, possibly hundreds of

miles from the nearest help was to be avoided at all cost. Maritime clothing

was not what it is today, everything became waterlogged quickly, and even

fur and sealskin clothing was heavy to wear and prone to becoming waterlogged

and frozen stiff. |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

In the 1948/49 season, the Kosmos fleet was made up of the following vessels - |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|